Dredging Equipment

Efficient, Field-Proven Systems Built for Demanding Mining Environments

Our Equipment

At Tennessee Dredge, we operate a modern fleet of advanced dredging equipment built to handle demanding projects across rivers, ponds, lagoons, and industrial sites. Our lineup includes high-performance slurry pumps and dredges from EDDY Pump, rugged earth-moving equipment and excavator solutions from Hawk Excavator, and reliable dewatering pumps from DAE Pumps, ensuring efficiency, durability, and dependable results on every job.

Excavator Pump Attachments

The EDDY Pump Excavator Pump Attachment converts standard excavators into powerful dredging machines, ideal for confined sites, shoreline work, and sediment removal in hard-to-reach areas. These excavator pump attachments are widely used for industrial ponds, stormwater basins, and riverbank work where traditional dredges are not practical.

Available in hydraulic excavator pump attachments or electric configurations, each attachment for excavator use delivers high solids-handling performance with minimal clogging. This makes them especially effective for industrial dredging services in Tennessee, municipal cleanup projects, and infrastructure maintenance where precision and mobility are critical.

Excavator Pump Attachment Capabilities

High-Volume Pumping Performance

Flow rates ranging from 700 to 4,000 GPM, delivering production capacity of up to 350 cubic yards per hour, depending on material type and site conditions.

Extended Reach Dredging Configurations

Compatible with long-reach dredge booms, enabling dredging depths of up to 85 feet; ideal for deep ponds, lagoons, and confined waterways.

Multiple Discharge Size Options

Equipped with cutterhead attachments for compacted material dredging, along with optional water jetting rings to assist with material breakup and agitation.

Liner-Safe Dredging Capability

Optional liner-safe configurations designed for dredging clay liners, poly liners, and concrete-lined basins without damage.

Flexible Power Configurations

Power options include hydraulic drive from the excavator, a dedicated hydraulic power unit, or electric drive, allowing adaptation to site-specific power availability.

Non-Clog and Cutterhead Configurations

Available with both non-clog pump heads and cutterhead designs to match slurry density and debris conditions.

Precision Dredging Technology

Integration with RTK GPS positioning systems enables accurate dredging control, precise cut profiles, and improved production efficiency.

Product Features

- Non-Clogging Design

- High Solids Handling

- High Viscosity and Specific Gravity Handling

- High Abrasives Handling

- No Critical Tolerances

- Low Maintenance

- Minimal Downtime

- Low Ownership Costs

Dredge Sled Systems

The EDDY Pump Dredge Sled is a proven solution for efficient sediment removal in ponds, lagoons, and shallow water bodies. Commonly used as a pond dredging sled or lagoon dredging sled, this system rests directly on the bottom and continuously removes sediment without disturbing surrounding structures.

For projects requiring controlled sediment removal, the Dredge Sled offers consistent depth control and strong solids handling. It is frequently deployed in farm ponds, wastewater lagoons, and small reservoirs throughout the region where access and stability are limited.

- Applications

- Dredging: Lakes, canals, lagoons, ponds, rivers, and waterways

- Mining:Process ponds, tailings ponds, and heavy metal recovery

- Wastewater: Sedimentation ponds, settling tanks, and digester tanks

- Energy: Power stations, oil refineries, and fly ash removal

- Industrial & Manufacturing: Chemical storage ponds and dewatering applications

- Agriculture: Lagoons, ponds, dams, canals, and desilting operations

Cable Deployed Dredge Pumps

Cable-deployed dredge pumps from EDDY Pump are designed for deep, narrow, or otherwise restricted environments where excavators and barges cannot operate. These systems are ideal for reservoirs, intake structures, and industrial basins requiring vertical access.

Available as cable-deployed hydraulic dredge pumps or cable-deployed electric dredge pumps, these units deliver reliable performance with minimal setup. Their ability to operate in tight conditions makes them a valuable asset for industrial dredging equipment in Tennessee applications and long-term sediment management programs.

Typical Applications

- Barge Unloading

- Deep Water Dredging

- Deep Water Dredging

- Mining

- Sand & Agg

- Oil & Gas

- Fly Ash & Coal Ash

Deploy Via Cable with

- Crane

- A-Frame Barge

- Excavator

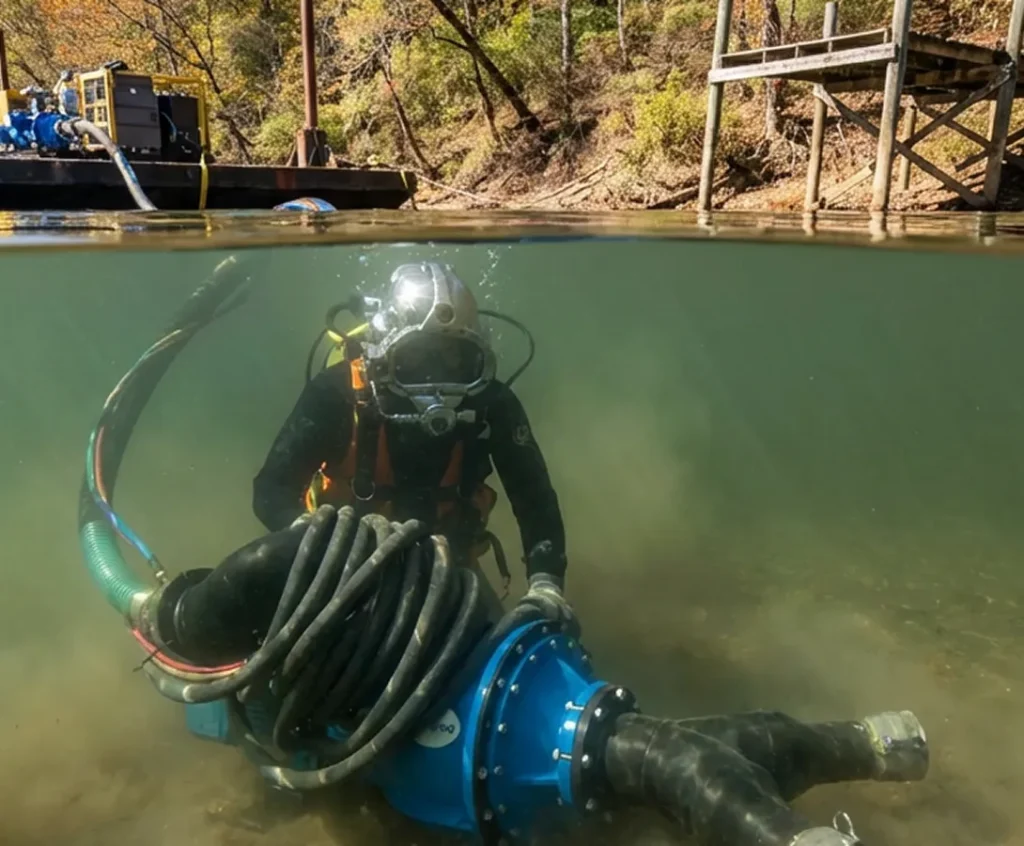

Diver-Operated Dredge Pumps

For precision underwater work, EDDY Pump Diver-Operated Dredge Pumps provide unmatched control and flexibility. These systems are commonly used for intake cleaning, pipeline exposure, marina maintenance, and targeted sediment removal around structures.

Offered as diver-operated hydraulic dredge pumps or diver-operated electric dredge pumps, these submersible diver-operated pumps allow crews to remove material exactly where needed without over-dredging. They are particularly effective in environmentally sensitive zones and confined underwater spaces.

Pump Features

- Non-Clogging Design: Engineered to prevent blockages in demanding applications

- High Solids Handling: Capable of moving dense, solids-laden materials

- High Viscosity & Specific Gravity Handling: Performs reliably with thick and heavy slurries

- High Abrasives Handling: Built to withstand severe abrasive conditions

- No Critical Tolerances: Reliable operation without tight clearances

- Low Maintenance: Reduced service requirements

- Minimal Downtime: Designed for continuous, dependable operation

- Low Ownership Costs: Lower lifecycle and operating expenses

Diver Dredge System Overview

- Standard 4” and 6” diver dredge configurations

- Handles high-solids slurries up to 60%

- Operates with one to three divers simultaneously

- Supports extended suction hose lengths beyond 300 ft

- Designed for long-distance pumping over 2,500 ft

- Available in electric or hydraulic-powered systems

Self-Priming Slurry Pumps

The EDDY Pump Self-Priming Slurry Pumps are built for high-volume, abrasive slurry handling where suction lift and continuous operation are required. These self-priming dredge pumps eliminate manual priming, reducing setup time and improving operational efficiency.

Used across industrial, municipal, and construction sites, these self-priming pump systems are available in diesel or electric configurations. They are frequently paired with long pipelines for remote sediment transport and are a core component of many dredging equipment in Tennessee deployments.

Self-Priming EDDY Pump Advantages

- Proven EDDY Pump power in a self-priming package

- Continuous priming supported by an integrated secondary vacuum pump

- Functions like a high-capacity wet vacuum

- Handles high-solids slurries from 30% to 70%

- Powered by electric or diesel drive systems

- Designed for non-clog, high-viscosity, high-SG, abrasive, and low-pH pumping

- Easily moves debris, including rags, string, rocks, and other foreign materials

- Flexible mounting options: skid-mounted, trailer-mounted, or stationary

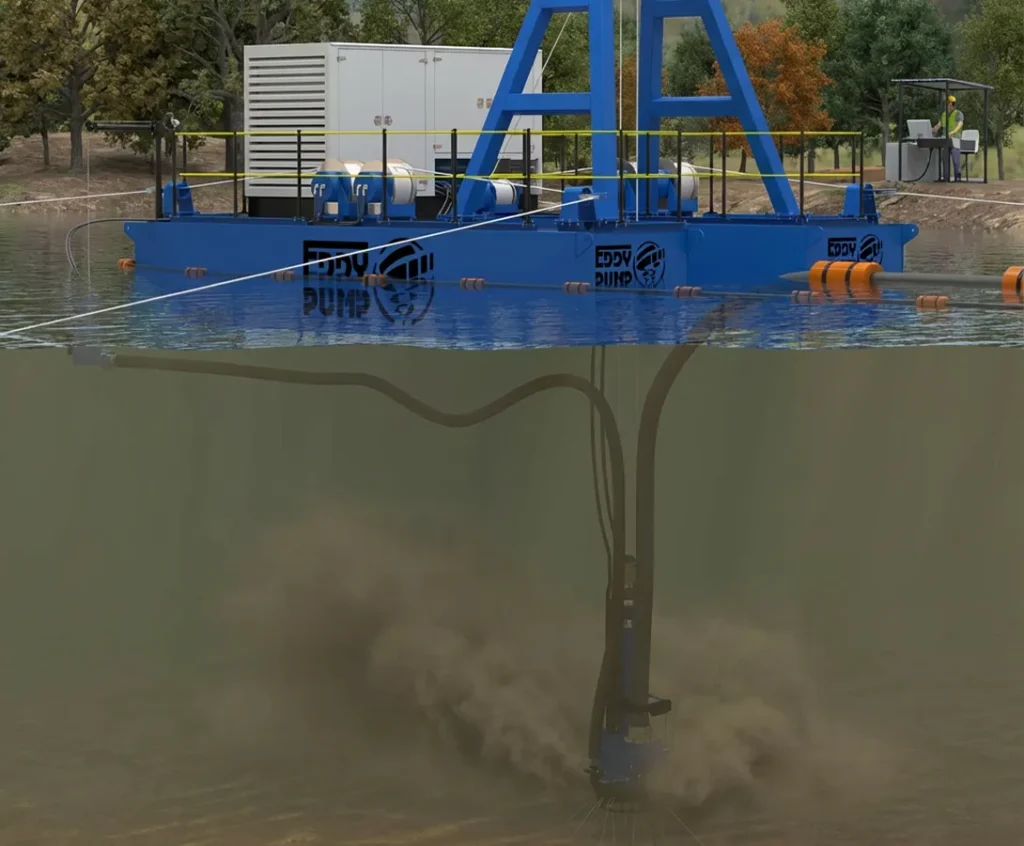

Remote Operated Dredges

Remote-operated dredges from EDDY Pump offer safe, efficient dredging in hazardous or hard-to-access locations. These remote-control dredging equipment systems enable operators to manage dredging operations from shore, reducing risk while maintaining productivity.

Ideal for ponds, stormwater facilities, and environmental remediation sites, these remote dredging solutions are widely used where access is limited or safety concerns prevent human-crewed operations.

- EDDY Pump Advantages

- Remote Operated, Autonomous Dredge

- Non-clog, High Viscosity, High Specific Gravity, High Abrasives, Low pH Pumping Design

- 40-70% Solids Pumping by Weight

- Ability to pump objects of up to 12 inches in diameter

- 100% American Built

- State-of-the-art research and Development Facilities on-site

- Easily process rags, string, rocks, and foreign objects

- Pump Features

- Non-Clogging Design

- High Solids Handling

- High Viscosity and Specific Gravity Handling

- High Abrasives Handling

- No Critical Tolerances

- Low Maintenance

- Minimal Downtime

- Low Ownership Costs

Earth Moving Equipment

Tennessee Dredge operates a fleet of excavators equipped with HAWK Excavator long-reach excavator kits and amphibious undercarriages, enabling work in wetlands, shallow water, and unstable ground conditions. This earth-moving equipment is essential for shoreline projects, canal maintenance, and marsh access.

Our machines are also fitted with RTK GPS positioning systems, providing high-accuracy grading and dredging control. These systems improve efficiency and reduce rework, particularly on large infrastructure and environmental projects.

- Long Reach Arm Kit Includes

- Boom x1 unit

- Stick x1 unit

- High-quality hydraulic bucket cylinder x1 unit

- Hydraulic tubing with clamp x1 set

- Hydraulic pressure hose x1 set

- Bucket linkage c/w 2 pins x1 set

- Bucket pin x2 pcs

- Arm cylinder pin x1 pcs

- Yoke pin x1 pcs

- EM bushings

- CE bucket c/w teeth x1 unit

- Seal kit, hydraulic bucket cylinder x1 set

Dewatering Equipment

Effective water control is critical on dredging sites, which is why we deploy EDDY Pump dewatering equipment alongside DAE Pumps systems. Our fleet includes submersible dewatering pumps and self-priming dewatering pumps designed for construction sites, mines, and industrial facilities.

These dewatering pumps handle groundwater, stormwater, and slurry with high solids content, ensuring stable operation and uninterrupted production. From temporary bypass pumping to long-term site drainage, our dewatering solutions support safe and efficient project execution.

Frequently Asked Questions

What types of dredge contracting services does Tennessee Dredge offer?

We provide a full suite of dredging services, including river, coastal, maintenance, and specialized industrial dredging, to support diverse project needs.

Do you handle dredging for marine and coastal environments?

Yes, we offer comprehensive marine dredging services, including beach nourishment, shoreline dredging, and port maintenance dredging tailored to coastal and offshore conditions.

Can Tennessee Dredge manage harbor and port dredging projects?

Absolutely. Our harbor dredging services include sediment removal, channel deepening, and ongoing harbor maintenance dredging to ensure safe navigation and efficient maritime operations.

Does Tennessee Dredge provide river and inland waterway dredging?

Yes, we specialize in river dredging and inland waterway maintenance, helping keep navigable channels open, reducing sediment buildup, and supporting flood control efforts.

What makes Tennessee Dredge different from other dredging companies?

Our local expertise, heavy-duty equipment, and decades of experience in complex regulatory and environmental conditions set us apart. Clients benefit from reliable solutions and strong project outcomes.

Do you offer dredging services for industrial facilities and manufacturing plants?

We do. Our industrial dredging solutions remove sediment from effluent ponds, wastewater systems, and heavy industrial sites, supporting efficient operations and regulatory compliance

Can Tennessee Dredge assist with municipal dredging projects?

Yes, we serve public-sector projects with municipal waterway, stormwater, and infrastructure dredging services that support community safety and environmental goals.

Do you offer emergency or rapid-response dredging support?

We provide emergency dredging assistance, including rapid sediment removal after storms, floods, or unexpected blockages, to restore critical water flow and access.

Are environmental considerations part of your dredging approach?

Environmental protection is central to our work. We use responsible dredging practices and compliance protocols to minimize ecological impact while enhancing habitat and water quality.

How does Tennessee Dredge support long-term maintenance dredging programs?

We develop customized maintenance dredging plans that include scheduled sediment removal, monitoring, and ongoing support to ensure waterways and infrastructure remain functional over time.